Any of the homeowners (baths, garages and other buildings are also considered) really wants his building to require repair as little as possible. And first of all, the safety of the foundation is of concern. For this, it is important not only to plan correctly and build correctly, you also need to divert water - groundwater and rainfall. The drainage system is engaged in groundwater abstraction, and rainfall is removed using the blind area. This equipment is not the most difficult device: any type of blind area is easy to do with your own hands. Work and costs are not very many, but it solves several problems.

Functions and Tasks

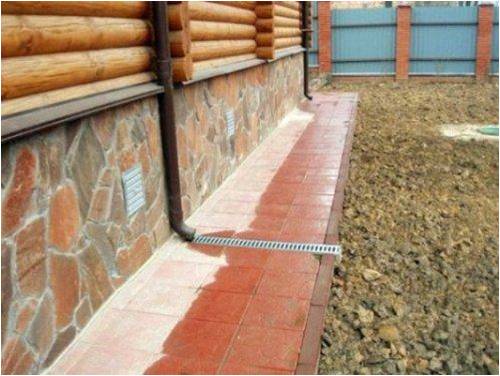

We have long been accustomed to the fact that there should be a path around the house: it gives the whole layout a finished look. Especially if it is combined with the finishing materials with which the building is decorated. In addition, it is practical: you can walk along the path. And the fact that the track is the blind area, and its main purpose, water drainage, is a successful combination of the properties and qualities of materials and thoughtful design.

The main function of the blind area of \u200b\u200bthe foundation is to divert precipitation from it

If you look from a utilitarian point of view, the blind area diverts rain and meltwater from the foundation. The second very important practical task that can be solved with its help is to insulate the foundation. If you put insulation under the track, it will protect the house from freezing, which will greatly reduce heating costs.

When do you need to do a blind area? Immediately after finishing the exterior walls, but before the basement is finished. Why is that? Because between the finish of the blind area and the wall of the house, a compensation gap must be left. This is an excellent path for water that flows down the wall of a house (it lands on walls with oblique rain, for example). But you can’t not make this gap - the foundation will collapse. Sealing the gap is also unrealistic. The way out is to make sure that the water does not get into the gap in any case. This can only be achieved if the base trim hangs over the seam. Then the water will drain a few centimeters further from the seam, and then fall into the drainage grooves. This can be done only if you first organize the blind area, and then bring to mind the base.

Why do we need the blind area of \u200b\u200bthe foundation, when we deal with it, we figured it out, now it remains to understand how to make it right.

Blind dimensions

It is necessary to divert precipitation from the foundation around the entire perimeter. Therefore, a protective belt is made around the house. The width of the blind area is determined depending on the type of soil on the site and on the length of the eaves overhang. In general, it should be 20 cm wider than the roof overhang. But SNiPom has set the minimum standards: on normal soils, the blind area is not less than 60 cm, on subsidence soils - not less than 100 cm.

The width of the blind area of \u200b\u200bthe house is at least 60 cm on normal soils and at least 100 cm on subsidence

Also in the manual to SNiP 2.02.01-83 there is clause 3.182 .. There are such instructions:

The blind areas along the perimeter of the buildings should be prepared from local compacted soil with a thickness of at least 0.15 m. The blind areas should be arranged with a slope in the transverse direction of at least 0.03. The edge marking of the blind area should exceed the planning one by at least 0.05 m. Water entering the blind area should flow freely into the storm drain network or trays.

From this passage it is clear that the depth depends on the technology chosen, but cannot be less than 15 cm.

Device technology

Any blind area consists of a base layer and a protective coating.

Backfill: what materials to use

The task of the underlying layer is to create an even base for laying the protective coating. Its thickness is about 20 cm. For these purposes, sand and gravel are often used, but native soil or clay can also be used.

Sand and gravel are used on well-draining soils. In this case, sand is first laid, spilled and compacted. Then - a layer of crushed stone, which is also compacted.

If the soil in the area is clay or loam, then it is better to use native soil. If with such soils, rubble or sand is laid around the foundation, then water will certainly be present near the house. Because it turns out that the density of the soil outside the underlying layer will be higher. This will lead to the fact that water will accumulate under the blind area. If with this design, a drainage pipe is laid around the perimeter of the bedding, the problem will be solved. And it’s effective. But there will be more work, and the cost of the blind area with drainage is higher.

Types of protective coating

The coating for the blind area must meet many requirements:

- must not let water through;

- should be frost-resistant;

- have increased resistance to abrasion;

- should not be destroyed by water.

It can be paving slabs or paving stones. Shape and color can be very different - choose based on the general design of the territory, houses of nearby buildings. The thickness of these materials is not less than 6 cm, only in this case they will withstand the harsh operating mode.

You can use slabs or tiles made of natural or artificial stone, you can lay tracks with large pebbles or pour crushed stone over all layers.

There is another species that is becoming increasingly popular - it is a soft blind area. It has few layers, but works efficiently. There may not even be any solid and waterproofing layer on top: you can fill the soil and plant grass or flowers. An interesting solution for a summer cottage or a country cottage.

All these options are not bad, but the cost of their arrangement is quite high. If there is a need or a desire to make cheap and cheerful - your choice of concrete blind area. There will be a lot of work, but the overall cost is low.

General principles

Depending on the soil on the site and the purpose of the building, different materials and the structure of the layers can be used, but there are some points that are always present:

How to make a blind area at home with your own hands

First, markings are made along the perimeter of the building with pegs and laces. Further, the procedure is as follows:

- The vegetative layer and a little soil are removed. The depth of the trench depends on the size of the underlying layer and the thickness of the protective coating. Usually 25-30 cm.

- The bottom is treated with herbicides. This is necessary so that plants do not grow on this site. They are able to destroy even concrete and asphalt, and sprout instantly between tiles or paving stones.

- The bottom of the trench is leveled, forming the required slope and compacted.

- The underlying layer is laid, rammed, while maintaining a slope. It is desirable to seal everything with a vibrating platform. Manual tampering is ineffective. The density is especially important when laying concrete, but it is advisable to tighten it well under tiles or paving stones: it will not fall through and warp.

- The protective coating is laid.

- A drainage groove is formed.

It is very short and sketchy. Each coating has its own characteristics, and each should be discussed separately.

Concrete blind area around the house

The most common coating is concrete. It turns out the most inexpensive. Traditionally, the underlying layer consists of spilled compacted sand (10 cm) of sand, on top of which compacted crushed stone (10 cm) is laid. As already mentioned above, such a scheme works fine on well-draining soils.

If there is clay or loam around the house, make the underlying layer from native soil. To reduce the effect of heaving and avoid cracking over compacted soil, pour 10 cm of sand, and already lay concrete on it. So the concrete will crack less, but you won’t completely get rid of cracking: especially in regions with severe winters. In such conditions, it is better to make a blind area of \u200b\u200bgravel or pebbles - there will be no problems with cracking. If funds allow, make it out of tiles. For harsh winters with correctly selected substrate layers, they stand well.

In general, on heaving soils, it is desirable to make a drainage that will drain the water flowing from the tape. It will be an effective and reliable solution. All the rest are only half measures. The drainage pipe is positioned so that water from the coating enters it.

The rules for concreting the blind area

Along the perimeter of the marked area, formwork is installed and fixed. Most often, a board of sufficient height, fixed with pegs and struts.

Reinforcement is often used to reduce surface cracking. For this, a mesh of steel wire with a cell of 10-25 cm is laid out on the finished underlying layer.

On top of the grid (if there is one), wooden planks treated with antiseptics are laid out. The thickness of the planks is 2.5 cm, and you can process them with hot drying oil. These slats are damper joints that will not allow concrete to crack when the temperature changes.

Planks are set while maintaining a bias from the house. They then “pull” the rule, aligning the solution.

To ensure that the surface is strong and smooth, iron is carried out. Almost immediately after pouring, while there is still cement milk on the surface, the concrete is sprinkled with cement (it can be crushed several times) and rubbed with a trowel or plaster grater. A thin, but strong, even and slightly shiny surface is formed on top. It is very resistant to abrasion.

The final step is concrete care. The track is covered with a damp cloth. During the week it is regularly moistened (sprayed from a hose or watering can). The fabric should remain wet. In order not to suffer with watering, you can close it with a film, but it is more difficult to keep it in one place.

Concrete for the blind area

For the blind area, standard sand and gravel concrete is used. Gloom is preferably not lower than M150. It is possible and higher: the higher the brand, the more durable the protective coating. The proportions of the solution for the blind area can be selected from the table. They are given for concrete grade M400 - not very expensive, normal in performance.

Insulated blind area

It makes sense to arrange a warmed blind area only in a house with heating. In buildings of seasonal residence, in which in winter the positive temperature is not supported, this makes no sense. The meaning of adding a double insulation layer:

If the insulated blind area of \u200b\u200bthe house is laid at the design stage, then one more reason is added: if this part is available, the reduction factors are used in the calculation. That is, the foundation has a lower height, and hence the cost.

A variant of the device of an insulated concrete blind area with a drainage system is shown in the video. Everything is painted normally, they did not specify only what to do if the layer of loose soil is more than 40 cm, which are required on the blind area. In this case, it is necessary to fill it with soil having a density higher than what is located on the site. If clay is on the site, then you can only use it. If it is loam, you can take either clay or loam.

One moment: to lay clay not in a dry state, but diluted to a paste state. The technology is old, but they haven’t come up with anything better. It is laid out in layers, trying to avoid the formation of air pockets - water will surely stagnate in them (or someone will settle).

Blade from crushed stone or pebbles

This is one of the types of soft blind area. It is easy to do it yourself. Such a system is used if there is a drainage system or the soil removes water well, and there is no clay or loam under the plant layer.

The order of work is this. A layer is laid in a dug trench on a leveled and compacted bottom. This material is not thick, but very elastic. He will not let crushed stone or pebbles into the soil. And the track will not sag. Crushed stone is poured and compacted from above. Layer thickness 10-15 cm, fraction 10-80 mm. Everything.

If desired, the gravel blind area can also be made insulated. Then in a trench on a compacted and leveled soil lay EPPS (extruded polystyrene foam) with a thickness of 50 mm, a high density geomembrane is laid on top, and pebbles or crushed stone can already be placed on it. But walking along such a path is undesirable.

Do-it-yourself blind area made of tiles or pavers

There are several options for the device, but the most optimal and universal are the “pies” using geotextiles.

For example, one of them is shown in the figure. It can be used to set up blind areas on heaving soils with severe winters. Note:

As a waterproofing, it is desirable to use geomembranes. They are made of high density polyethylene. By brands: you can take Tefond, Izostud, Fundalin, Technonikol Planter Standart, etc. They stand in the region of 150-250 rubles / m 2.

Geotextiles are of different grades and different densities, with different functional purposes. Choose based on the geology of the site. Their price is from 15 to 50 rubles / m 2.

When installing the blind areas with your own hands, the main thing is to make sure that the water leaves the foundation, and does not collect in the sand or gravel layer near the house. What will happen if the soil is heaving (clay or loam), the underlying layer is made of sand and gravel, and there is no drainage.

At the end of construction activities for the construction of the building, it seems that the building is completely ready. The desire to engage in internal improvement and move in faster makes the developer miss some nuances. One of these points is the blind area around the house, significantly extending the life of the building, protecting the base of the building from moisture.

There is an erroneous opinion that the blind area of \u200b\u200ba private house is not a necessary element of the structure. However, do not postpone its construction until tomorrow. After all, the bearing capacity of an unprotected foundation, which is deformed as a result of intensive absorption of moisture, gradually decreases.

The blind area of \u200b\u200bthe house is one of the important aspects in creating a long and comfortable operation of the house itself

In construction, various edging options are used, performed along the perimeter of the building. To ensure a long service life of the building, reliable protection of the foundation, it is important, observing the technology, to properly blind around the house. Let us dwell in detail on its purpose, parameters and varieties. We select the materials and tools necessary for the performance of work. We will understand in detail how, according to construction technology, a blind area is made around the foundation of the building.

Why do you need to blind area

The blind area of \u200b\u200ba private house is a structural element around the structure, made with a slope around the perimeter of the foundation. It performs serious functions, the main of which are:

- reliable protection of the base of the building from the effects of rainfall;

- water drainage along the perimeter of the foundation of the structure into storm sewers;

- reducing the depth of freezing of soil around the structure, which reduces heat loss;

- prevention of soil swelling at low temperatures;

- preventing damage to the surface of the foundation by the roots of plants;

- providing the finished view of the building by creating a transition between the base and the soil.

After completing construction work, it is necessary to complete the edging along the contour of the structure before the onset of cold weather, so that the moisture-saturated layer of soil during freezing does not violate the integrity of the base.

After intense rains or snowfalls, or snowmelt near the building, water may accumulate

Design parameters

- The width of the edging is more than 60 cm. To ensure ease of movement, you must expand the track to 100 cm.

- Exceeding the width over the roof contour of more than 20 cm. This contributes to the ingress of precipitation to the surface.

- Closed track configuration, completely encircling the building. The perimeter foundation must be protected.

- The slope of the surface towards the soil in the range of 1–10%, which corresponds to a slope of 1 to 10 cm per meter of width. At elevated angles, gliding is highly likely during glaciation.

- The thickness of the surface layer of concrete pouring around the building, comprising 7-10 cm. The parameter depends on the depth of freezing of the soil, increases to 14 cm at high loads.

- The installation of a border that impedes damage to the base of the root system of plants.

- The rise of the edging above the zero mark at the level of 50 mm. This makes it difficult to flood with precipitation along the outer edge.

Compliance with regulatory requirements will ensure comfortable operating conditions and durability of the structure.

When creating a drain, the creation of a blind area is a must

The blind area around the house - the necessary materials and coatings

A blind area is made around the building using various materials:

- concrete paving stones. Specialized stores offer materials of various colors, original configurations. The presence of rounding significantly reduces the likelihood of chipping edges. The dimensions of the pavers allow you to perceive the loads associated with the movement. Edging elements enhance aesthetic perception. The material is resistant to deep freezing, temperature changes and allows you to quickly perform masonry with filling the gaps between the elements of sand;

- natural stone. Stone pavers are made from natural granite in various shades. The material is supplied in the form of chipped or sawn blanks. Products are available in standard cubic form or in the form of a parallelepiped. Laying is carried out similarly to paving stones, cast from concrete, onto a previously prepared base up to 50 mm thick from fine gravel or sand. After sealing the joints, the formed stone mass is compacted;

- concrete. The use of concrete mortar is an inexpensive solution that provides water resistance and high strength. For pouring, soil preparation and installation of wooden formwork for concreting are carried out. Expansion joints along the contour of the building are also performed. The concrete surface decorated with colorful pebbles 1–5 cm in size is well perceived;

To create a strong long-term blind area, you will need to correctly select high quality materials and strictly observe the technological aspects of construction

- paving slabs. The usability of the plates is the ability to easily replace damaged items. Tiles are square in shape with a side of up to 0.5 m and rectangular products up to 1 m in length. Along with the standard gray color of products, you can purchase multi-colored material that has a smooth or decorative texture. When the size of the edging is multiple to the width of the plates, you can avoid trimming and quickly complete the work;

- crushed stone. An easy-to-manufacture option, used for the close location of groundwater and the execution of a drainage system around the structure. Along with crushed stone, expanded clay and ordinary gravel are also used. For ease of movement, the material layer should be carefully tamped with a preliminary installation of geotextiles. It complicates the growth of weeds, protects the material from mixing with the soil.

Concreting is widely used. To perform the work, prepare the tools and necessary materials:

- Shovel, wheelbarrow and buckets needed when removing the soil layer and transporting materials.

- A device for manual tamping, which allows to perform the compaction of the array.

- Building level for horizontal control.

- Materials for waterproofing protection.

- Timber for the manufacture of formwork.

- Steel reinforcement or finished mesh with a square mesh side 10 cm.

- Sifted sand.

The blind area should form with an inclination. So the water will drain from the walls of the building

- Crushed stone of medium size.

- Portland cement brand M300.

- Clay.

- Extruded polystyrene foam for insulation.

- Building cord and pegs for marking.

The blind area of \u200b\u200ba private house - features and types of structures

Regardless of the type of construction and manufacturing technology, the blind area is a path along the perimeter of the building. Consists of the following layers:

- underlying. The base is fine gravel, clay or sand. The damping layer forms a compacted base for the outer coating;

- fine. It is a topcoat that protects the foundation from moisture. Provides aesthetic perception.

There are various options for making a blind area around the house. The blind area is divided into the following groups:

How to make a blind area around the house - stages of work

We will say right away that there are no regulatory documents in our country that would regulate the correctness of the creation of the blind area. Separate standards talk about its purpose, the required dimensions, the angle of inclination and other information. The sequence of actions is not scheduled. However, there is a lot of world experience in this matter, which would be foolish not to take into account.

These documents say that the blind area is located near the building in order to protect it from getting wet along the perimeter of the structure. That is, it is part of water protection measures. Why protect the soil, you ask? Yes, then, when it is saturated with water, moisture begins to penetrate the foundation if it is poorly waterproofed. During frosts, this causes increased heaving of soil and the destruction of concrete.

Also, the abundance of water in the soil can affect its bearing properties. This is inherent in clay and loamy soils. As a result, they cannot cope with the load from the structure, and it begins to sag, causing serious deformations, which can lead to cracks in the walls and foundation. Therefore, it is so important from the very beginning to take care that the soil around the house does not get wet. In addition, it reduces the load from the waterproofing of the foundation.

The blind area is also part of the architectural appearance of the whole house - without it, the structure will not look attractive, even if expensive and beautiful materials are used to decorate the facade. Everything should be harmonious. And again, the blind area can be used as a path - it can be disguised and made integral with the decoration of the adjacent area.

What are the requirements for the blind area

Not a single normative document requires linking the size of the overhang of the roof with the necessary width of the blind area, although the connection, at first glance, can be traced out naturally. It is often possible to stumble upon information that you need to retreat 20-30 cm from the projection of the edge of the roof overhang. In fact, this is not required, since all water from the roof must be discharged through the system. If you did not provide it, then, indeed, these parameters can be correlated, but not necessary. The blind area can have two minimum sizes, depending on the type of soil - 70 cm for sandy and 100 cm for clay.

An unorganized drain from the roofs of two-story houses (no more) should have an overhang of at least 60 cm in width. In this case, the difference with the width of the blind area will be only 10 cm. It follows that the recommendation for a protrusion of 20-30 cm is purely recommendatory in nature - many do this, but there is not much point in it, because even if the overhang is wider than the blind area of \u200b\u200bthe correct size and water will fall into the ground, it simply will not pass this distance underground. The main thing is to protect the necessary centimeters.

There are more loose soils, which are called subsidence. There are two types of them, and the requirements for the width of the blind area here will differ significantly. Type 1 - 1.5 m or more, Type 2 - 2 m or more.

Interesting to know! If a pit was dug for a house, then the width of the blind area on any soil should go beyond its borders by at least 40 cm.

As for the angle of inclination of the blind area, it should fall in the range from 1 to 10%. For subsidence soils of both types, the minimum is 3%.

Varieties of the blind area

There are three variants of the blind area, so first decide which one suits you best.

Hard blind area

This option is a solid tape around the perimeter of the entire structure. It is made of ordinary concrete or asphalt concrete.

Interesting to know! Asphalt concrete is a fairly plastic material, therefore, it tolerates bending loads well. For this reason, it does not need reinforcing with a reinforcing layer of reinforcement or steel mesh. Concrete made of cement does not have such properties, therefore reinforcement is strictly necessary.

Such a blind area is arranged according to exactly the same principle as pavement tracks. The only thing is that you need to strictly observe the slope for a good drainage of water.

Both types of material are able to resist the penetration of water, of course, not 100%, but this indicator is quite high, due to which there is an effective protection of the soil around the structure. From here one can immediately deduce a certain rule - in such a blind area there should be no cracks and tears, since they will serve as direct routes for the penetration of water into the soil.

Another rule for such a blind area is the need for a small deformation gap between it and the structure in case of thermal expansion of the material. So that there are no open slots, they are then filled with elastic materials, and then finished.

The next type is called semi-rigid. It is made of clinker brick and paving slabs. Laying of the material is carried out exactly the same as on the tracks, but be sure to lay a waterproofing layer in the base. Use for this membrane and film materials. Such a coating can be arranged on dry sand or on a concrete base.

The simplest and most inexpensive option is a soft type blind area. It implies the organization of tapes of water-repellent clay around the house - the material is rammed, after which it can be decorated with crushed stone or marble chips on top. Such a blind area was made in the old days, although even now it can be used for small buildings and country houses. To increase its effectiveness between layers of clay and crushed stone, you can additionally lay a waterproof film.

Nowadays, a blind area based on a profiled membrane has become very popular - it belongs to the category of soft ones. It becomes so. First, a trench is rummaged around the entire house with a depth of 25-30 cm, the bottom of which is rammed so that a slope is obtained. Then a membrane is placed - it can be laid with an overhang on the foundation. Next, drainage is made of sand and gravel, and then a layer of soil. On such a blind area, you can safely plant a flower garden and not be afraid that the house will remain unprotected.

The problem with oversaturation of soil with moisture often depends on the region. If you encounter this problem, you can solve it by installing a drainage device. In we detail, by examples, consider all aspects of this issue.

The second name of this blind area is hidden. This is an elegant and beautiful solution that will definitely decorate your home, but you will not be able to walk on it, which will be a significant drawback.

Why the blind area may become worthless

The desire of our people to constantly save is not some greed, but a necessary measure. Well, we don’t have such income to afford everything that technology requires. However, there are things on which it is simply a crime to save, as as a result, everything results in even greater expenses. The list of such phenomena, of course, also includes the blind area.

People tend to underestimate the power of natural phenomena, due to ignorance or careless attitude to business. And by the way, a simple freezing of wet soil can squeeze out and crack a whole concrete slab, if it is not strong enough - we remind you that concrete does not belong to the category of elastic materials. The integrity of the blind area is also affected by other factors that should be taken into account:

Advice! If there is an outlet for water from the base of the building, a separate gutter must be provided under the tap to drain the water. This also needs to be done at the ends of the drains.

What thickness should the blind area be?

How thick should the concrete blind area be to cope with the amount of water that falls on top of it? We are not talking about other options, since everything is determined there by the thickness of the material used, while monolithic concrete must be precisely calculated. The essence of such calculations is not to determine the minimum thickness - it must be taken at least 7 cm, but, on the contrary, to calculate the maximum thickness at the house.

Make it easy. You know the angle of inclination that you will give for the blind area. Next, check how much you want the blind area to protrude above the rest of the area, for example, 7 cm. We take into account the width of the tape, draw the resulting right triangle and find the height of the back side. To do this, you can use the Pythagorean theorem or the rules for finding lengths by the magnitude of the angle. If the calculations are complicated for you, then find the calculator you need online and get the result in a few seconds.

How to make a blind area with your own hands

Now that you and I are aware of the basic requirements, let's see in what sequence the work needs to be done. To do this, we need the following materials and tools.

Table 1. Required materials.

| Materials, photo | Description |

|---|---|

| We will use Portland cement of brand 400 or 500. We do not recommend taking less, since now there is already a high probability of running into low-quality material. |

| The sand should be clean, so we take either river or washed. We also recommend pre-sifting it to avoid various debris and organic impurities getting into concrete. |

| Crushed stone or gravel will serve as a large filler for concrete. The fraction of the material should be no more than 40 mm - check this parameter before purchase. |

| Ideally, the base of the blind area should be insulated, which will create additional protection against freezing of the soil. For these purposes, rigid extruded polystyrene, for example, penoplex, is used. |

| For the blind area, you need to form a flat formwork. For this we use an edged board 25 mm thick and not less than the thickness of the blind area. |

| The reinforcing layer will be made of steel mesh. You can use reinforcement, but this is a clear excess and unnecessary waste. |

From the tools - everything is as usual for working with concrete:

- Concrete mixer, if you do not want to do everything manually.

- Vibrating plate for high-quality ramming of the base - can be replaced by manual ramming.

- Shovels - bayonet and shovel.

- Tub into which finished concrete will merge from the concrete mixer.

- Buckets or stretchers - in the second case, the tool will replace the tub.

- Construction level to check the slope of the bottom of the trench.

- Rule and trowel for leveling concrete mass.

- A simple carpentry set to put together formwork - a hammer, a hacksaw and nails.

Prices for popular concrete mixer models

Concrete mixer

Other devices may also be required, which we will mention later, if necessary.

So, we pass to the beginning of work.

Step 1 - marking and excavation.

First of all, we need to accurately mark the borders of our blind area. We use twine and wedges for this. We already wrote about these parameters above. Further, excavation is carried out - for a good blind area, 20-25 cm will be enough. Spent soil should be immediately taken out of the site, as it will interfere with work.

In this case, it is worthwhile to remove residual roots from the trench, any sharp objects and large stones. The bottom of the trench is leveled as far as possible and rammed. You won’t have to ramp much, since the integrity of the soil below was not violated by us. The exception is the cases when the foundation pit fell asleep earlier - here you need to especially try. The bottom of the trench should be tilted away from the house.

Step 2 - sanding.

The next step is sanding. Pour the material evenly, then smoothly level it with a piece of board or a rule. Please note that the formwork is already installed on the master’s photo. He did it even before digging a pit. You can do the same, or organize it after all the layers of the foundation are arranged — the essence of the person will not change.

Step 3 - you need to wet the sand.

To make sand easier to compact, it is recommended to moisten it. Moreover, using a watering can, like the master in the photo, will not be enough here. It is much more effective if you supply water through a hose and sprayer so that the sand does not wash out. You need to wet the entire layer of sand cushion, so do not spare water. During the passage of water through the sand, it will already begin to be compacted. If you spill it well enough, then subsidence may become immediately noticeable. If you do not have a vibrating plate at hand, we advise you to do this all day several times.

Step 4 - tamping sand.

Next, the sand is rammed. We go through each section of the tape without missing anything. After tamping, be sure to check whether the slope that you gave the bottom of the pit is preserved, if not, you need to fill up the sand and repeat the procedure until you achieve the desired result.

Ramming machine prices

Rammer

Step 5 - the device of the waterproofing layer.

In principle, there is no need to lay a film under a concrete slab, since concrete itself will not pass water into the ground. However, such a measure would not be superfluous. She will play a role if it so happens that the blind area will crack. As a result, due to the bias that we gave earlier, water will be diverted from the house. The waterproofing material is overlapped, while it is desirable to coat the joints with bituminous mastic.

Step 6 - insulation of the base.

Using a heater is also an optional step, however, if you want to do everything as efficiently as possible, lay this layer and your house will be guaranteed to be protected.

Step 7 - Foaming seams.

Since we decided to warm ourselves, we do it right. Slots remain between the polystyrene plates, which will serve as cold bridges, so it is recommended that they be filled with polyurethane foam.

We remind you that it is advisable to make a deformation seam around the perimeter of the structure. How is this implemented? Some put boards, but then they are difficult to pull out, and there is little sense from such work. For this reason, we advise you to organize a fixed formwork from the same foam, but of a smaller thickness - 2 cm is enough. Its upper edge is set so that with the external formwork it immediately forms the desired angle of inclination. You can also use foamed insulation, but you can’t extend the rule by it.

Step 8 - laying the reinforcing mesh.

We install the formwork, if this has not been done before. It is knocked down by nails and strengthened by wedges driven into the ground. Inside, it is desirable to coat it with bitumen so that the tree does not draw moisture into itself. You can also wrap the material with plastic wrap.

Now we are laying a mesh that will strengthen our concrete. Be sure to overlap, otherwise the tape will not be reinforced over the entire area equally, and cracks can also appear. Ideally, the reinforcement should be raised a couple of centimeters above the base using special stands, but so few do so because of the inconvenience of subsequent movement - the mesh is simply laid on top of the insulation, and then slightly lifted up after filling.

Step 9 - installation of partitions for expansion joints.

We break our tape into sections with wooden partitions. At the same time, they should not reach the base so that concrete flows freely under them. It is also possible to organize seams, and cutting concrete in the right places, immediately after pouring it. Here, everyone chooses for himself.

Step 10 - pouring concrete.

It is prepared from the following ratio: 1 part cement, 3 parts sand and 4 parts crushed stone. In this case, you need to add so much that the solution does not turn out to be very fluid.

We fill our formwork, distributing the mixture with a trowel and leveling it with the rule. In this case, the surface is smoothed as much as possible. It will not be superfluous to use a deep vibrator to make our tape more dense and durable.

Step 11 - Concrete Fermentation

Bay concrete, to increase strength, its surface must be ironed. To do this, dry cement is poured on top in its pure form and smoothed evenly with a trowel.

Ready concrete requires maintenance for at least one week. So that when it does not crack, it should be regularly spilled with water. When it is hot outside, cover it with an additional dark film. If you follow all the prescribed points, you will get an incredibly strong formwork that will last for decades.

Video - The blind area around the house

Video - The blind area around the house with your own hands

The blind area of \u200b\u200bthe house is one of the important aspects in creating a long and comfortable operation of the house itself. It creates protection for the foundation and soil around the circumference from moisture. After intense rains or snowfalls, or melting snow near the building, water can accumulate. It can also drain from the roof. Moisture can be damaging to the topsoil and reach the foundation. If this happens, then the bearing potential of the foundation will seriously weaken. As a result, the entire structure washes.

When creating a drain, the creation of a blind area is a must. The gutter will create for the ground a defense against water falling from the roof, but does not protect against rainfall.

It is extremely important to correctly build a blind area when you have a foundation at shallow depths. Its sole is quite close to the surface, and water can reach the very depths of its laying without any problems. Then the strength of the sole will disappear, the sole itself will sag, and the foundation will lose its shape and begin to collapse.

A blind area should also be created with a well-equipped buried foundation.

To create a strong long-term blind area, you will need to correctly select high quality materials and strictly observe the technological aspects of construction.

The blind area of \u200b\u200bthe tiles.

Determination of the width of the blind area

The main task of the blind area is protection. And its width is that parameter, which should be obtained as possible. Its recommended minimum value is 80 cm. And the maximum numbers - this is a purely master's business. There are no standards. The necessary width will ensure the absorption of moisture into the soil far from home.

When determining the width, it is worth considering another task of the blind area - walkway around the building. The blind area should provide free movement along this path: no walks sideways or tight against the wall. Given this factor, the width should be set in the range of 100 - 250 cm.

The blind area should form with an inclination. So the water will drain from the walls of the building. According to Soviet standards, the slope parameter is as follows: 5 - 10 cm per 100 cm wide. That is, the edge of the blind area, whose width is 100 cm, will reach a height of 5 - 10 cm near the wall of the building. Its other edge will turn out on the same level with the earth. So it turns out pretty steep descent. It is optimal for quick and efficient water drainage. But the movement along such a blind area will be problematic. If the angle of inclination is reduced, the flow rate drops significantly, water can generally accumulate on the surface. Although the movement along the blind area will turn out comfortable.

Given the perfect surface of the blind area (evenness, smoothness), an inclination of 1 cm is acceptable. However, it will be difficult to move on a similar surface in winter time - very slippery.

If a material having a rough surface is used for the assigned tasks, the minimum value of the slope is 1.5 - 2 cm.

When the blind area is created around a non-residential building, for example, the recommended angle at the entrance is as follows: 2 - 3 cm. So the surface will receive high-quality protection from rainwater. That will rapidly drain, penetrating into it and not freezing in the cold. And your garage will not have puddles and ice.

Material selection

This task should be approached very seriously. There are different options for materials to create the blind area. Considered the most popular reinforced concrete.

When applied, the work is performed according to the following algorithm:

- Site cleaning for future construction.

- Reinforcing rods (minimum diameter - 6 mm) form a grid. Its cells are as follows: 30 x 30 cm. The cells are connected by knitting wire.

- Installation of formwork. For this, boards are involved.

- Fill the formwork.

Before creating the blind area, its basis is prepared: along the perimeter of the structure along the width of the blind area, the upper soil layer is eliminated - about 13 cm. At the walls, the depth should slightly exceed the specified parameter. The poured concrete mixture should drain to the house, squeezing it slightly. Any other fastenings of the blind areas to the structure are not required.

Then marked border blind areas. Pegs come into play. They are driven in. A cord stretches between them. The bottom of the trench is covered with a sand layer of 5 cm. Concrete will rely on it.

If the soil in the working area is sandy, the use of sand can be excluded. On this layer are put formwork, reinforcing cage, concrete pouring follows. Reinforcing elements should be totally concentrated in the concrete base. For this, the base rises a little.

Concrete is created in the following proportions:

- cement M400: 1 share,

- sand: 2 lobes,

- crushed stone: 4 or 5 shares.

The blind area is made of concrete.

Radioactive materials

If you intend to build a blind area from ash - the result of coal combustion at a thermal power plant, be careful. Ash can be a source of radiation. And this will adversely affect the health of residents.

As a rule, coal mining is carried out at Russian mines. There is a very high level of radiation. At thermal power plants, radiation checks are not carried out. An important factor there is the ash content of coal. Therefore, by purchasing ash and engaging in its construction activities, you run the risk of seriously worsening your health. To reduce the risk, purchase ash with a dosimeter. This device will calculate its radiation level.

Also in the category of radiation materials is cinder block. Its composition also includes ash. There are cases of determining a very high level of radiation in residential buildings created from such blocks.

Extremely rarely, increased radiation is also found in foundation blocks and reinforced concrete slabs. In construction activities, instead of cinder blocks, blocks from sawdust can be used. This option is completely clean in environmental terms.

Metal can also give off radiation. This applies to both black and colored varieties of it. A dangerous background is most often present in molten metal. The echo of Chernobyl tells here. A lot of metals from this zone were exported and remelted. And there is some chance that buying a metal product for the blind area, you get the "element" of Chernobyl. When purchasing, also use a dosimeter.

Work on the coating for the blind area

After absolute hardening of the concrete mixture, a coating can be laid on it. Very often, the coating is formed from curly paving elements (FEMs), or from granite pavers.

The former differ in their quality and appearance. Acid-resistant bricks with parameters of 12 x 25 x 5 cm are considered high-quality options. They perfectly cope with the loads from frequent movements and walking, as well as environmental conditions.

Standard FEMs do not have the required strength. This negatively affects the time of their service. It stretches for 5 years. After this period, their initial appearance is completely lost. Such coverage should last at least 10 years.

Paving stones are an excellent option for coating. Its strength is high, decent service life, there is a rich color range. It can be used as a mosaic, to form intricate patterns. Its main disadvantage is associated with its enormous price.

Coating example

The nuances of self-creation of blind areas around the house

In this paper, it is worth paying attention to the following nuances:

- Do not erect a blind area immediately after the construction of the basement. When backfilling is performed, the trench is filled with soil previously extracted from it. That is, black earth, clay, etc. are used. To a certain extent, there is subsidence of any soil. It takes time for it to completely sink. If you build a blind area immediately, without waiting for this subsidence, then in the event of moisture penetrating into the soil, it will begin to sag, changing the shape of the blind area. And cracks form on its surface. To prevent such a picture, do backfill from sand, which easily passes water. When you competently pour and level it, the blind area can be created in 24 hours. Although this construction is better to begin after the construction of the box of the building or 8-12 months after work on the foundation.

- To cover do not use porcelain tiles. It has a smooth slippery and traumatic surface. In addition, she has a very modest service life. After all, it is laid directly on the concrete plane, which expands in the cold. And such a coating soon bursts.

FEM laying principles

To lay this material, use a mixture created from a bucket of cement (grade M400) and 3-4 buckets of sand, as well as 70 grams of detergent. The last component protects the created composition from subsidence.

There is a more economical version of laying - on sand. But the service life of the coating in this situation will be short-lived. When moisture penetrates the sand, the material will sag, it will need to be re-laid or completely replaced.

Another economical option with similar characteristics is laying on a dry mixture. So the pleasant appearance of the surface will hold a little longer. Therefore, the first proposed option remains the most optimal.

Example

Creating Blind Protection

As you know, the main task of the blind area is protective. But it is desirable to defend this structure itself from water flowing from the roof. Here it is necessary to arrange a quality outlet in the format of gutters. They will be organized along the entire perimeter of the roof. So the water will first be in the gutters, along them it will go into the drain pipe. As a result, it will still end up on the blind area, but its runoff height will drastically decrease. The impact on the surface of the blind area will also decrease.

By old standards, tap technology was used for buildings with more than two floors. Today, a challenge is arranged in any private houses.

Examples:

It will not hinder the blind area to additionally insulate. So the soil will freeze less in the cold. For such purposes, castling is performed in the concrete composition: expanded clay instead of crushed stone.

Another good insulation technique: fill the blind area in two layers., Between them a heater is arranged, for example.

Final requirements for the blind area:

- Optimum width for efficient flow and comfortable walking: 1-2 m.

- Optimum slope according to the same criteria: 1.5 cm (per meter of width).

- Creating the foundation, it is necessary to dig a trench with a slight bias to the residential building. The blind area should be in close contact with the house throughout its depth.

- The optimal and safe material is reinforced concrete. It guarantees an excellent result in terms of strength and durability.

- The best option for coating is acid-resistant brick - FEM. It is laid on a concrete mixture.

- No matter how many floors appear in the erected house, a high-quality drainage system is required. It will seriously increase the operational life of the blind area.

An example of a finished blind area with a drainage system.

Video instruction

Video by Alexander Kvasha on creating a blind area with your own hands is not only one of the most popular. The authors of the material did not turn off the possibility of commenting, so viewers were able to actively criticize the material presented and analyze errors in detail.

Blind areas around the building are made immediately, as soon as the work on finishing the exterior walls has been completed, but before the basement decoration has been started. This is due to the fact that it is necessary to overlap the expansion joint between the coating of the track and the wall of the building so that water cannot get into it because of the protruding surface of the base.

As for screw, deep columnar or pile types of foundations, in this case there is not even a need to make a blind area, but they are mostly made in order to serve as a pedestrian walkway or as a decor for arranging the yard.

Design features of the protective coating

Such a coating must be created around the entire perimeter of the building, since it is necessary to protect the foundation from all sides. As for the norms and requirements that apply to it, they are all described in SNiP 2.02.01-83, which states that regardless of whether the blind area around the house will be done with their own hands or with the involvement of specialists, its width on normal soil does not should be less than 60 cm, and on soils that tend to sag - from 100 cm.

In any case, the width of the coating should not protrude from the cut of the roof by at least 20 cm. The maximum width is not established by the regulations.

A hard coating must be laid only on a dense base, which has a thickness of at least 150 mm. It is very important to pay attention to the fact that the deviation of the blind area from the building should not be less than 0.03%, taking into account the excess of the lower edge over the planning mark of not more than 50 mm. As for storm waters, they should be diverted to special trays or stormwater (storm sewers).

A good insulated blind area, which should fully fulfill all its functions, consists of 3 layers:

- Waterproof (top).

- Underlying (sand with crushed stone or gravel).

- The warming (expanded polystyrene).

Sometimes experts use another layer, which is used as a geotextile, the main task of which is reliable waterproofing from groundwater. Groundwater can cause problems every spring, so the use of such a layer is quite relevant. Among other things, it will protect against weed germination.

Materials for the top layer

Before you make a blind area around the house, you need to decide on the materials that will be best suited for these purposes. There are a large number of materials that differ in their capabilities.

- Among the most commonly used, economical and simple materials, clay is common. She is able to create a sufficient hydrobarrier. Most often it is used in rural areas, but with regard to modern buildings, the use of clay has long been abandoned, since more effective technologies have replaced it.

- A more modern and common option is the blind area of \u200b\u200bthe concrete coating. Without investing a lot of money, such a blind area can be done very quickly, with your own hands. Concrete has a high service life and strength. In addition, to improve its appearance, you can cover it with paving slabs or other coating.

- The blind area can be finished with paving slabs, which are laid on a mortar or cement-sand mixture. Often it is used as a creation of a single decorative style of the yard. The tile is quite durable and will not cause any problems when laying.

- You can also use paving stones, which is also suitable for these purposes, if you lay it on a sand pillow, pre-tamping it. It has a pleasant appearance for the eye, but it is several times higher than paving slabs and has some difficulties during installation. When using this material, it is imperative to complete the joints to completely seal the top layer.

- In order to enjoy the blind area for many years and not think about repair, it is recommended to use natural stone. But it is worth noting that such material can only be accessed by wealthy people.

- As for asphalt, it is very rarely used due to the fact that it emits an unpleasant odor in the summer heat and does not have a high level of strength, if you do it yourself. A purchase from the factory will cost much more than a concrete blind area around the house.

Along the entire perimeter of the blind area, trays must be laid for water drainage. Such trays are made of asbestos cement or ceramics. Not in the last place is a well-made drain. For some works it is recommended to invite specialists if there is not enough theoretical or practical knowledge.

How to do it yourself

To begin work on creating a concrete version of the protective coating, you must initially prepare a specific list of materials and tools, which includes:

geotextiles, which in principle can be replaced with clay;

- portland cement 500 or Portland cement 400;

- reinforcing mesh with a cell diameter of 10 by 10 cm;

- washed or river sand;

- processed board or bitumen to process it;

- crushed stone fractions not more than 4 cm or gravel;

- polystyrene foam boards.

Once all the material has been prepared, you need to take care of the necessary tool for the job:

- hammer;

- concrete mixer;

- hacksaw;

- tamper or possibly a plate;

- mason trowel;

- shovels: shovel and bayonet;

- rule for plaster;

- container for concrete;

- level.

To correctly make the blind area with your own hands, step-by-step instructions will help to avoid mistakes and unnecessary costs. The whole process begins with the fact that you need to carefully markup. Marking should be done around the perimeter of the building. As soon as this stage is completed, you can remove 30 cm of soil and tamp the bottom.

The next step is to spread geotextiles on a rammed bottom or, if clay is used, then it must be densely compacted to approximately 6 cm thickness. On top of this you should make a mound of sand with a thickness of 5 cm, and this layer also needs to be densely packed. Sand acts as a protective layer, so that the crushed stone does not damage the waterproofing layer.

Now is the time to put formwork from the boards along the edge of the trench. Some for this purpose use sheet material for lack of boards. Be sure to make the formwork 5 cm higher than the expected level when preparing the formwork. Now is the time to start backfilling a layer of gravel with gravel, which must be rammed to a thickness of 8 cm and sprinkled with sand on top. Sand is not required much, it is necessary so that during pouring concrete mix it does not penetrate into the voids between the rubble.

Before making a blind area, it is necessary to provide for the installation of expansion joints in a width of 1-2 cm. This is necessary because in hot weather the concrete layer can expand, and at very low temperatures - break. This seam will prevent such a situation. Such a seam is made using a waterproofing material 1-2 cm thick or roofing material.

In addition, approximately every 100-200 cm at all corners of the house across the blind area, it is necessary to make pieces of boards up to 3 cm thick and install them. This is necessary to compensate for possible extensions.

Naturally, before installing such transverse rails, they must be carefully treated with a bituminous composition so that they do not rot. It is necessary to install such rails so that their upper edge is flush with the concrete poured in the future.

Concrete layer

To maximize the strength of concrete, it must additionally be reinforced with a metal mesh. The most optimal cell size will be 100 × 100 mm. Some craftsmen use wire with a diameter of up to 8 mm for these purposes. In fact, it can also be used, but only in this case it is necessary to bandage all the individual elements together.

Once all the preparatory work has been completed, you can begin to prepare a mixture of concrete and begin to pour it. You can buy ready-made concrete grade M200-250, but it is worthwhile to understand that this will significantly increase the overall estimate.

Before you fill the blind area around the house with your own hands, you can prepare concrete in the ratio:

- gravel - 4 parts;

- sand - 2.5 parts;

- cement - 1 part.

Water is best added to the concrete mixer in the last turn in small portions and knead until a homogeneous mass of medium density.

Filling the blind area is as follows. The process must be approached as responsibly as possible. The mixture is laid on top of the reinforcing mesh so that the slope of the blind area to the building is at least 3%, and the mesh should be slightly above ground level. Thus, we obtain a formula in which a level increase of 3 cm should be for every meter of width.

To remove air bubbles from the concrete solution, it is necessary to apply the so-called bayonet. To level the surface as much as possible, it is necessary to carefully compare the surface with constant control of the slope angle using a level using a building trowel and the rules for plastering.

To make the surface even more durable, you can use a special technology of ironing. To do this, it is necessary to sprinkle with an even layer of dry cement on the surface of a wet solution, which has not yet had time to set. If you do this without a sieve, then you have to use a spatula and gently rub it.

If the blind area is done in dry and hot weather, then the following steps must be performed. To prevent the concrete from drying out, namely, grasping, it is necessary to cover it with a wet cloth and pour water over certain periods. The first 3-4 days you can’t stand on it. Only after this time will its top be seized, and it will be possible to step on the blind area without fear of damage.

Paving slabs

Before you properly make a blind area around the house from paving slabs, you must first make another base for it. This is due to the fact that the tile does not have such a level of strength, unlike concrete.

The base must be very tight. The first clay layer should be increased, after which a mixture of sand and cement will be laid, on top of which the tile is laid.

It should be noted right away that in the case of paving slabs, the trench should have a depth of 45 cm. Only in this case it will be possible to obtain a high level of stability. As the bottom layer, it is necessary to compact the clay so that its thickness reaches 30 cm. This will provide normal protection in the spring in the event of a rise in groundwater level. A border is placed on top of this layer along the edge of the trench, which should not be higher than the level of tile laying along the edge of the blind area.

As the second layer, gravel or crushed stone is used, which also needs to be well tamped to a level of 10-15 cm thick. This layer should be level with the ground. On top of it, it is necessary to lay geotextiles so that no plant can sprout through it. Now you can start pouring the mixture of sand and cement, and then start laying the tile itself.

It is very important to adhere to the technology accurately.

Paving stones

What is the paving of the paving stones? This is one of the best materials for these purposes. It looks great and has a greater thickness compared to the previous material and better resistance to external influences. It is noteworthy that, due to its properties, paving stones can be laid directly on the sand. The trench can have a depth of 15 cm. It is enough to lay the geotextile, then put the curb and tamp the sand so that it does not reach the end of the trench a little. Now it’s enough to just lay the material.

Attention! Despite all the simplicity of laying and good appearance, it is necessary to remember the high cost of paving stones.

After laying, it is necessary to give the masonry tightness with a cement mortar, which must be laid in the joints between the stones. It is necessary to ensure that the border is not located above the upper level of the coating.

Soft option

To learn how to make a soft blind area around the house, you first need to deal with the term itself. By this is meant crushed stone, pebble, cobblestone, gravel and other materials under which a layer of sand is located (clay is sometimes used), which are covered with a plastic film.

Among all the existing modern options, this is the most economical type of coating, but it is worth considering the low operational period, which does not exceed 5 years. Once this period has passed, you will need to repeat the procedure for laying soft or any other blind area.

It is worth paying attention to the bias of clay and polyethylene. This point is important due to the fact that water is not drained by the top coating, but directly by the waterproofing layer.

Insulation scheme

It is very important to learn how to make a blind area around the house, to think about its insulation. This is especially true for regions with traditionally low temperatures and for almost the entire territory of Russia in the winter. Thanks to warming, it will be possible not only to keep the foundation intact, but also to keep the heat in the house.

For a heater it is necessary to take high-quality material that does not rot, has a sufficient level of density, is hydrophobic and durable. Expanded polystyrene or polystyrene are best suited for these parameters.

Insulation works should be performed in 3 steps, which must be done during the creation of the blind area:

- It is necessary to lay a hydroisol or ruberoid on clay or a thin sand pillow so that part of the roll extends to the side walls.

- The second step is to insulate the basement wall. For this, it is necessary to fix thermal insulation on it. When fixing the sheets, it is necessary to connect them as tightly as possible with grooves, and when this is not possible, then it is required to seal them using mounting foam.

- As for the horizontal layer, it must be laid directly on the lowest layer. To save money in this case without loss of quality, you can use a layer of foam, and on top of it fix the polystyrene foam. When laying, it is necessary to control that the seams between the layers do not coincide vertically.

On the Internet you can find tips that with this type of insulation, you can use expanded clay instead of crushed stone, but this can even do more harm. The problem is that empty cavities remain in the bulk expanded clay, where moisture will begin to appear over time, which will negatively affect the thermal insulation properties.

Blind operation and repair

Now you know why you need a blind area around the house, why it is very important to properly care for and, if necessary, repair it. Over time, chips or cracks may occur on the surface of the concrete. Often this situation occurs due to subsidence of the soil, with the wrong selection of expansion joints or the use of low quality materials.

To repair such cracks, it is necessary to use sand, asbestos and bitumen primer, which are mixed into a homogeneous mixture, but before that it is necessary to slightly increase the crack and clean it of dust using water pressure. After it dries, it is necessary to pour the mixture inside.

If the damage is too large, then it is necessary to increase them even further to the extent that they can be poured with a new portion of concrete. If necessary, damage can even be further reinforced with a rod or wire. After the place dries, it must be treated with a primer.

parlini.ru Repair of apartments, villas and houses.

parlini.ru Repair of apartments, villas and houses.